Late last fall when the mornings turned quite chilly (frost on the ground) the starter on the DR began to make some funny sounds, similar to that of a wheezing duck -- a kind of sqeaky, squealing noise. It sounded exactly like this video I found on YouTube:

After reading of similar complaints from other DR owners on ADVRider, the diagnosis sounded plausible: dry armature inside the starter motor. Requires a bit of lubrication. The end of the armature opposite the drive gear rests in a bushing (not a bearing). Apparently these bushings are made of a sintered material that contains some type of lubricant, whic is released slowly as the sintered material wears away, thus providing a permanent lubrication system. However, if the sintered material gets heated up or burned, it glazes over which prevents the sintered material from lubricating the shaft properly. In warmer weather, it doesn't matter much but when the cold weather hits, the dry rubbing makes a squeaky sound. I guess the best solution would be to replace the bushing in the end cap of the starter motor. But an easy fix that will last a couple of years is to simply put a dab of grease in the bushing. This quick and easy fix takes about an hour and costs nothing. It's also a good way of checking the internals of the starter motor, especially the parts that normally wear out (like the brushes).

First step: because you will need to remove the Cam Chain Tensioner (CCT) it's important to make sure the engine is at top dead centre (TDC) on the compression stroke. To do this, remove the plug on the flywheel cover so you can line up the timing mark. Then rotate the engine by hand (using a ratchet on the flywheel, or by turing the rear tire slowly with the bike in 3rd, 4th, or 5th gear). Remove a spark plug and keep your finger over the hole so that you can tell when the air in the cylinder is being compressed.

The timing mark on the flywheel as seen through the inspection hole.

I also use a plastic drinking straw in the spark plug hole

to make sure that the piston is at the top (but you need to be

sure it's at the top ON THE COMPRESSION STROKE.

That's why you keep your finger over the hole).

As a safety precaution, it's a good idea to disconnect

the + positive terminal from the battery.

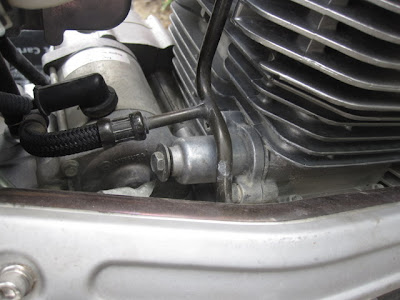

Remove the exhaust header pipe

Remove the upper and lower bolts for the oil line

and move it out of harm's way.

Moving the oil cooler line out of the way gives

unobstructed access to the starter motor.

I like to put the bolts and crush washers back in

place to avoid losing them, and also to avoid getting

dirt inside the engine.

Remove the cam chain tensioner (CCT)

Then, remove the starter.

The starter motor removed.

End cap removed reveals the brushes as they are pressing

against the commutator with the wound springs.

A small dab of grease squeezed into the hole at the end of the armature.

A small dab of grease in the end-cap bushing.

I cleaned the guts of the starter using air compressor to blow the dust out.

Cleaned the rubber O-ring and cleaned up the casing a bit.

Wiped down all the grease and crap from the engine.

Getting ready to wind up the spring in the cam chain tensioner (CCT)

**note the long shaft sticking out: it needs to be wound back in before re-installing the CCT.

Remove the bolt that plugs the hole at the end of the CCT (right side in the photo above, bolt is removed)

This exposes a small flat screw inside. Use a small screwdriver to wind up the spring as you push in with your thumb. Keep turning the screwdriver slowly until you hear/feel a click. Then the pin is locked in and you can take your thumb off the end.

CCT pin is locked once the spring has been wound up with a flat scredriver.

Reassembly:

1. install the starter and clutch cable bracket

2. install the CCT and then use the flat screwdriver to unlock the spring

(which will apply tension on the cam chain)

3. re-connect the oil cooler line.

4. re-install exhaust header pipe

5. re-connect positive battery terminal

All buttoned up.